INSULATING GLASS

FAQ

Below are the most frequent questions on the subject. Click on the question to read the answer.

How is an insulating glass made?

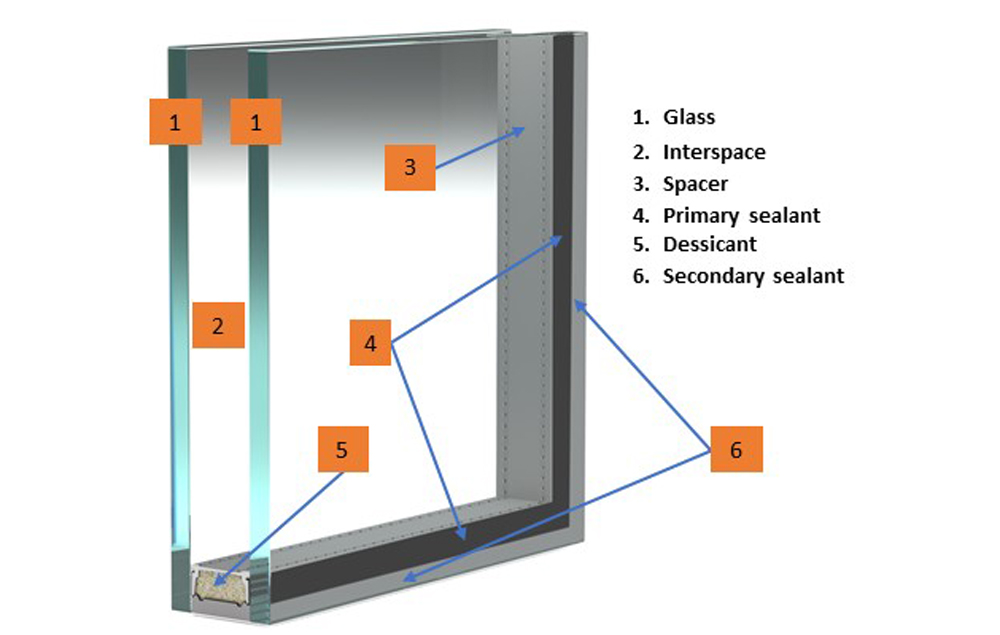

The insulating glass is a panel manufactured with two or more glass sheets, joined by a spacer profile section on which two organic sealants are generally applied. The double barrier thus obtained guarantees the tightness of the gap, inside which there is dehydrated air or inert gases (Argon or Kripton), and its mechanical stability over time.

How much does the thickness of a glass affect the thermal insulation?

In insulating products, normally, the thickness of the material has a decisive influence on the passage of heat. In glass, this does not happen and a thick sheet has almost the same thermal insulation as a thin sheet. To limit the passage of heat, it is always required to use an insulating glass (PDF N. 1 - Passage of the thermal flow).

How are the differences between insulating glass windows assessed?

The insulating glass windows are by no means all the same. Their differences, from the point of view of their features, can be divided as follows:

- Performance: they are represented by the ability of the double glass to meet safety requirements and light, energy, solar, thermal and acoustic factors;

- Qualitative: they are established by the constructive adequacy to maintain the required performance over time.

Where can I find the quality features of the ALU-PRO products?

The ALU-PRO spacer profile sections comply with the provisions of the UNI EN-2/3/6 standards in force. The relevant Test Reports are not published on the website but are available from the Sales Network or can be requested to the Technical Service Dept.

How can I reduce my energy costs?

To reduce energy costs, it is required you use windows and doors that have excellent thermal performance in both winter and summer. These assessments must be developed taking into account the location, exposure and use of the building.

To evaluate the thermal insulation of a window, the elements to be taken into account are the values of its overall thermal transmittance Uw and that of the transmittance of the insulating glass Ug. The lower are these numbers, the better the performance will be (PDF N. 2 – European Standard EN ISO 10077).

What do thermal conductivity and thermal transmittance indicate?

Conductivity or thermal conductivity (λ = W/mK) is the specific property of each material and is defined as the quantity of heat transmitted through 1 m2 of a material with a thickness of 1 meter subjected to a temperature difference of 1 K (Kelvin).

Thermal conductivity depends on the nature of the material, but it is in no way influenced by its shape that can therefore be of any type. The smaller is this value, the better will be the insulating capacity of the material, i.e. the heat flow that can pass through it is lower.

Thermal transmittance (U = W/m2K) is the specific property of each structural element and is defined as the "heat flow that passes from one fluid to another through a 1 m2 surface wall and temperature difference, between the two fluids, of 1 K (Kelvin).

The smaller is this value, the lower is the quantity of energy dispersed by the construction element, i.e. the thermal insulation is better.

What does linear thermal expansion indicate?

Linear thermal expansion is a particular type of expansion that occurs on bodies that have the size of one of the three dimensions decidedly higher than the other two. It takes place when the temperature of a body increases and affects, in particular, metal wires and bars.

It is calculated starting from the change in temperature by means of the linear expansion coefficient of the material. This coefficient is determined experimentally and is constant for each material.

What does equivalent thermal conductivity indicate?

Energy saving has required the study of spacers for insulating glass panels capable of reducing, as much as possible, the passage of heat. This was handled by using materials with ever lower thermal conductivity, with lower thicknesses, when possible, thus decreasing the metal used until, in some types of products, it was completely eliminated.

The design of the profile section has also been transformed in many products. All these changes have made it increasingly difficult to calculate the conductivity with the method provided for by the UNI EN ISO 10.077-2 standards. At the end of 2012 the "Warm Edge" working group, promoted by the German Institute for Structural Engineering with the collaboration of IFT in Rosenheim and important manufacturers of profile sections for double glass, developed a methodology for measuring the flow heat via hot plate.

The heat flux values measured with this method, expressed in W/mK, are called equivalent thermal conductivity and marked with the symbol λeq,2B. The Test Reports of the Psi values issued by BF (Bundesverband Flachglas) of Rosenheim, they are shown the lower part of the documents.

What does linear thermal transmittance mean?

The linear thermal transmittance indicates the amount of heat that passes through the area where the frame, glass and spacer interact according to the properties of each of them and is characterized by the Greek symbol Psi Ψ (PDF N. 3 - Linear Thermal Transmittance Ψ).

The Psi values of our spacers are specified on the Test Reports issued by BF of Rosenheim and visible on the "PRODUCTS" pages of this website by opening the PDF called "Psi Windows" or "Psi Facades".

In the Test Report there are 8 values obtained with 4 different types of windows. The upper four relate to double glass insulating windows Ug = 1.1 W/m2K, while the lower ones refer to triple glass windows Ug = 0.7 W/m2K.

How can the thermal performance of an insulating window be improved?

For decades, the most used insulating windows has been manufactured with two 3- or 4-mm glasses separated by a 12 mm aluminium spacer. Thermal insulation (Ug = 2.8 W/m2K) was obtained through the dehydrated air contained within the cavity.

This value can be improved by using a low-emission glass instead of a normal one, thus replacing the dehydrated air with a gas and, finally, increasing the number of cavities (triple window). In this way, the value of the thermal transmittance Ug can be 0.4 W/m2K (PDF N. 1 - Passage of the thermal flow).

What are low emission glasses?

They are glasses on which a metal deposit has been applied that is able to reflect radiation in the long infrared range (low emissivity), with a consequent significant reduction in thermal dispersions.

The glass remains perfectly transparent because the very delicate deposit is invisible. In practical use, the treatment is positioned inside the interspace. In English these products are called low-e.

Can the thermal performance of a window be improved?

From a thermal point of view, the quality of a window is assessed by verifying its thermal transmittance Uw. This overall value is related to the size of the window, the type of material used (wood, metal or plastic), its processing and the type of insulating window installed.

As all other conditions are equal, a further improvement is still possible and can be achieved by using the warm edge spacers in the manufacture of the insulating window.

What are warm edge spacers?

Most of the insulating windows on the market were manufactured using a spacer, between the sheets, in aluminium. Aluminium is an easily machinable, inexpensive material, but has a very high thermal conductivity λ = 200 W/mK (PDF N. 4 - ALUMINUM SPACER).

To limit the passage of heat through the spacer, over time, materials have been developed that, having a lower thermal conductivity, are identified as warm edge.

What are the warm edge spacers for?

The warm edge spacers, both in winter and in summer, drastically reduce the passage of heat passing through them. The temperature of the perimeter area of the glass sheet will thus be similar to that of its central part.

How are warm edge spacers made?

ALU-PRO, in its product range, has different types of warm edge spacers. The first ones placed on the market and still used are entirely made of stainless steel, a material that has a thermal conductivity λ = 15 W/mK that is much lower than that of aluminium λ = 200 W/mK (PDF N. 5 - CHROMATECH).

Others are manufactured by combining stainless steel with plastic materials. Still others are made with the copolymer structure covered with a special film impermeable to the passage of steam and gases (PDF N. 6 - CHROMATECH ULTRA F, PDF N. 7 - MULTITECH A, PDF N. 8 - MULTITECH G, PDF N. 9 - THERMIX TX PRO).

What are the benefits of the warm edge spacers?

The significant reduction of the passage of heat through the warm edge spacers has the main advantages as shown below (PDF N. 10 – Product's advantages):

- reduction of heating and air conditioning costs with consequent savings on the relevant costs,

- achievement of a more pleasant ambient temperature in the areas surrounding the windows with the possibility of using spaces previously little used,

- removal or minimization of condensation on the edges of the insulating windows,

- return to a better energy class,

- significant contribution to the reduction of CO2 emissions into the atmosphere.

Why is there condensation on my windows?

Condensation can form on the insulating window and on its frame or only on the insulating window. It is formed almost exclusively on the window if it is metallic (in aluminium or iron) without thermal break and, therefore, with significantly lower thermal features than the insulating window. Condensation can affect three different areas of the insulating window:

- the glass surfaces inside the double glass,

- the surface of the glass inside the building,

- the surface of the glass outside the building.

The appearance of traces of humidity inside the cavity of the insulating window (initially they are circular in shape in the centre of the sheet), highlights an initial defect of the product or that it has reached the end of its life.

The insulating window in these conditions is no longer able to allow viewing the external environment and to ensure the thermal insulation function (PDF N. 11 - Two reality: identical problem).

Why does condensation form on the internal surface of the windows?

Condensation on the surface of the glass inside the house is a natural phenomenon that occurs whenever the temperature of this internal face drops down to the so-called "dew temperature", which, in turn, depends on the temperature and the relative humidity of the ambient air.

The higher is the percentage of relative air humidity (RH), the higher must be the surface temperature of the glass so that the condensation phenomenon does not occur (for example, with 90% RH the temperature of the glass must be higher than 18.3°C).

What are the optimal humidity conditions in a living room?

Relative humidity can take on high values, if there is no constant renewal of the air, even if the rooms are free of steam sources (pots of hot water, laundry hung out to dry).

In a normal living room of 3.5 meters x 4.5 meters, equal to 42 cubic meters, with air at 20°C and humidity:

- RH of 50% (value considered excellent) contains a total of 365 grams of steam (8.7 g/m3 x 42 m3 = 365 g),

- RH of 90%, the steam content, at the same temperature, rises to 655 grams (15.6 g/m3 x 42 m3 = 655 g).

So, an increase of 300 grams of steam brings relative humidity from 50% to 90%.

Since it is known that an adult person releases about 50 grams of steam per hour, the increase considered above corresponds to the amount of steam released by two people in less than three hours.

How can I prevent condensation on my windows?

The appearance of condensation can be limited creating convective currents on the surface of the glass so that the humidity is removed and, above all, trying to limit its concentration (airing the rooms or vacuuming the particularly intense one created in the bathrooms and kitchen rooms).

The use of insulating windows with a particularly low thermal transmittance and equipped with warm edge spacers significantly reduces this phenomenon (PDF N. 12 - No more condensation on the glasses).

Why does condensation form on the external surface of the windows?

The formation of condensation on the surface of the glass outside the building is a very rare phenomenon, which can sometimes be observed at night or at the first light of dawn. It happens that the sheet temperature can:

- when the sky is clear and in the absence of wind,

- due to the important radiation towards the sky,

- poor heat loss passes through the insulating windows,

drop below the outside temperature with consequent condensation. This phenomenon, therefore, must be considered as a proof of the excellent thermal insulation of the product.

Why having replaced the windows now condensation forms on the windows?

Sometimes customers of residential homes, after replacing their windows, complain of the appearance of condensation that previously did not occur with the old windows. The problem is not related to the new windows! Humidity is present in the air inside the home/building. These are the possible causes:

- boiling of food

- use of shower and bathroom

- rooms without or with poor suction and/or ventilation

- drying of linen

- presence of a large number of people in a room

- underfloor heating

- covering of windows with curtains that prevent air circulation

- low ambient temperature

- no air exchange by opening the windows.

The new windows are airtight and, therefore, free of the drafts of the old ones that allowed the involuntary exchange of air. In the new conditions, the humidity can no longer escape and, therefore, condenses on the coldest areas of the room (normally on the glasses).